💥Bulk Updates💥

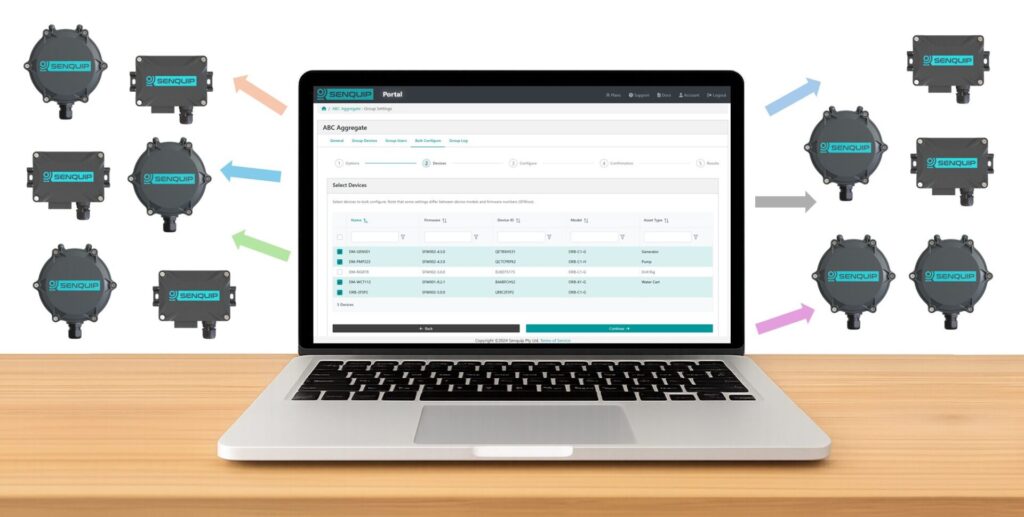

Managing large fleets just got easier. With the Senquip Vision Dashboard, you can now update multiple devices at once, saving time and reducing errors.

Bulk Features Available Today:

💥Change individual settings across multiple devices

💥Update firmware

💥Import complete configurations, including page layouts and scripts

💥Adjust alert options for multiple devices 💥Upload CSV and other files to devices

Bulk updates work across all Senquip devices on Basic and Hosted plans, with support for both group updates and hand-picked selections. No more updating devices one by one; make changes across your fleet in seconds.

Case Study – Pioneer Pump

Since 2017, Pioneer Pump has been a leader in applying telemetry to its diesel pump sets. That commitment has now been extended to its advanced electric pump sets. In collaboration with IPU, remote monitoring and control has been implemented using Senquip telemetry.

The challenge was to provide a robust system capable of handling complex Modbus communications, live fault diagnostics, and seamless remote adjustments across a range of drive settings. The Senquip solution delivered:

🌍 GPS tracking and geofencing

⚠️ Real-time status and fault alerts

🎮 Remote start/stop and speed control

📱Customisable alerts via SMS, and email

The result is a reliable, user-friendly dashboard with custom controls and widgets. Already deployed across a major UK rental fleet, the system improves efficiency, reduces costs, and enhances reliability. Pioneer Pump and IPU are now working on extending the functionality to multi-pump and standby applications.

Feature Update – Common Data Keys

To make it easier to compare data across different devices and machine types, Senquip has introduced a set of common data keys for scripts. These are fixed keys with standardised units that allow consistent reporting and easier analysis, regardless of the underlying machine.

For example:

The first set of common keys covers core engine and fuel metrics, including:

- Engine Hours, Idle Hours, Run Hours

- Fuel Consumption and Fuel Economy

- Engine Speed, Load, and Temperature

- Coolant, Oil, and Transmission levels, pressures, and temperatures

- Distance travelled and Fuel Level

The standardisation of these values enables Senquip Vision dashboards to show more meaningful fleetwide comparisons with simplified setup.

Python Script for Accesing Senquip API

The Senquip Cloud API makes it easy to integrate telemetry data directly into your own applications, dashboards, or analytics tools. With real-time access to asset data and centralised device management, the API provides a flexible way to extend the power of the Senquip platform.

A new application note shows how to get started using Python, with simple examples for:

🪄 Retrieving JSON data for developers

🪄 Exporting CSV data for engineers and analysts

These quick-start scripts demonstrate authentication, querying devices, and returning measurement data—making it straightforward to adapt for your own use case.

See the full application note on the Senquip Documentation site for details.

Battery Profile

Senquip devices now include a new setting under General > Battery Profile. This allows you to choose how the internal battery is managed.

By default, the profile prioritises longer battery lifespan over maximum capacity. This is especially useful in high-temperature environments, or when a device remains on charge continuously.

The update helps extend service life and maintain reliability, even in demanding applications.

Pioneering UK Hydrogen Trial

The project demonstrated that the UK’s high-pressure Local Transmission System (11,600 km of pipelines) can be repurposed to safely carry hydrogen, marking an important step towards a low-carbon energy future. In a UK first, live operational tasks such as welding and flow stopping were successfully performed on a 30 km stretch of hydrogen pipeline between Granton and Grangemouth.

By proving that existing infrastructure can be adapted for hydrogen, the trial paves the way for regional hydrogen hubs and a resilient backbone for the UK’s net zero energy system.

Senquip and CANopen

Did you know Senquip devices work seamlessly with CANopen? This makes it easy to integrate with modules like the MicroControl μCAN.4.ti-BOX.

The unit measures up to four thermocouples with high precision. It suits applications in process control, environmental monitoring, and machinery diagnostics.

With CANopen, a Senquip device gives you real-time access to temperature data. No gateways. No complex control systems. You can monitor conditions, spot faults early, and track performance over time.

See the full application note on the Senquip Documentation site for details on wiring, setup, and scripting.

⭐DACH Distributor⭐

Senquip is excited to announce the appointment of b-plus Group as our distributor for the DACH region. Their expertise in automotive software, measurement technology, and mobile automation makes them an excellent partner for Senquip.

“Germany has a long history of building quality machines. We’re excited to have the opportunity to contribute to that legacy with Senquip’s rugged telemetry solutions, now supported in the region by b-plus.” – Norman Ballard, CEO, Senquip

“At b-plus, we have always focused on delivering innovative engineering and measurement technology to support our customers. Partnering with Senquip allows us to extend that commitment by offering rugged telemetry solutions that keep critical assets connected, even in the toughest environments. We’re proud to bring this capability to customers across the DACH region.” – Harald Bügel, CEO, b-plus

Together, Senquip and b-plus look forward to supporting customers across the DACH region with innovative, reliable solutions that drive efficiency and enable smarter decisions.

Drill Rig Monitoring

Another beast leaves the workshop – built to perform, built to impress. 💥

From concept to completion, the MCM Auto Electrics team has designed, constructed, and delivered a system that pushes the limits of productivity, efficiency, and ESG performance.

Packed with next-level capability:

✅ Senquip QUAD – real-time remote monitoring of every critical metric.

✅ PV500 Glove-Touch Display – fully custom software for:

💥Precision drill parameters

💥Live engine diagnostics

💥Hydi Hydrogen Injection control

✅ PV101-R2 – instant engine overview at a glance.

✅ 3 × UControl MC3 units – the brains behind seamless system control and data management.

Why it matters:

This isn’t just a machine – it’s an integrated, intelligent solution ready to work harder, smarter, and cleaner.

Proudly designed, built, and delivered by the team that makes impossible look easy.

Senquip Out and About

Australian Technologies Competition

Senquip has been selected as a finalist in the Australian Technologies Competition.

The competition is a premier growth and awards program for innovative Australian technologies with global growth potential.

Distributor Training

This quarter, Senquip delivered a hands-on training session with our distributor, Macquarrie Corporation. The session focused on configuration best practices, real-world applications, and an in-depth look at the new Senquip Vision Dashboard.

Vision provides businesses with powerful tools to gain insights from their data, improve utilisation, reduce fuel consumption, and support ESG reporting.

The Macquarrie Corporation team are now well-prepared to deliver even greater value to their customers.

Exhibitions

Automation Group at the AWA NSW Conference.

Join the Hydrotechnik team at the Environmental Services & Solutions Expo in Birmingham.

Why Base64 🪲🪲🪲🪲

Senquip devices automatically encode all text into Base64 before transmitting it in a JSON packet. This ensures that unprintable characters, which JSON cannot handle, are removed.

To support developers, two scripting commands are available:

- SQ.atob(string) – Decodes a Base64-encoded string and returns the result.

- SQ.btoa(string) – Encodes a string and returns it in Base64 format.

The SQ.atob function is especially useful for decoding strings received from the serial port.

🪲🪲🪲 A recent update has fixed an issue where decoding would stop if a null character was encountered. See the Senquip Firmware Changelist for more information.🪲🪲🪲